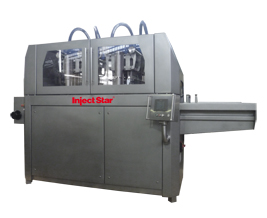

Injectors

Injectors from Inject Star convince particularly through the innovative technology combined with the modern design. The results are absolute homogenous injection rates as well as an optimised brine distribution within the product.

Injectors from Inject Star therefore leave nothing to be desired and represent the perfect solution for small and medium-sized companies as well as the industry.

Features

• Red meat, poultry, fresh meat, fish & seafood.

• Meat with and without bones.

• Working width from 300 to 800 mm.

• With crank or linear drive (depending on model).

• With manual or touch screen computer control (depending on model).

• With up to 4 needle heads (depending on model).

• “New-Twist-System” for an easy and quick exchange of processing tools.

• Various needle/knife combinations.

• Uncooled / cooled.

• Various optional supplementary equipment.

Technical specification

• Working width from 300 to 800 mm.

• Capacity red meat 1.750 kg/h – 8.500 kg/h.

• Capacity poultry 800 pc/h – 2.200 pc/h.

• Injection rate up to 50 % – up to 100 %.

• Control : Manual or “ISC-B05” touch screen computer control.

• Number of strokes : 10 – 50 strokes/min.

• Lifting height : 50-220 mm.

• Feed system : synthetic conveyor bel.

• Needle tools : 15 – 39 pc 2fold 4 mm needles for red meat or 3 mm needles for poultry.

• Filter system : with suction filter.

• Pump : 1 pc rotary pump.

• Pump pressure : 1.0 – 2.5 bar.

• Nominal power : 400 V / 3 / 50 Hz.

• Total power requirements : 4 – 19 kW.

• Dimensions length x width x height : IS-300 (1.7 x 0.9 x 2.0 m) / IS-400 (2.0 x 1.0 x 2.0 m) / IS-590 (2.1 x 1.2 x 2.0 m).